Case Study: Precision & Throughput Achieved

Power Brace Mfg. Delivers Hybrid Welding Solution for High-Volume, High-Complexity Component

The Challenge: Balancing Volume, Quality, and Labor Volatility

A long-standing customer approached Power Brace Mfg. with a critical, high-volume part—a complex bracket requiring significant welding. The customer's main concerns were:

- Sustained Throughput: The volume required continuous, reliable production that could not be interrupted by internal process variations.

- Quality Consistency: The welds were integral to the product’s structural integrity, demanding high repeatability.

- Cost & Labor Risk: Relying solely on manual welding introduced the risk of inconsistent cycle times and exposure to skilled labor shortages, threatening the competitive pricing required for the contract.

The customer needed a partner capable of not only producing the part but also innovating a process that shielded their supply chain from market volatility and human process variation.

The Power Brace Mfg. Solution: Hybrid Automation

Power Brace Mfg. collaborated closely with the customer's engineering team to design and implement a hybrid welding process—a strategy that leverages the strengths of both human expertise and advanced robotic automation.

The Hybrid Process Breakdown:

1. Skilled Human Expertise (Setup & Precision): Our skilled welders handle the critical, nuanced aspects of the job:

- Part Assembly & Tacking: Ensuring perfect fit-up and fixturing.

- Complex Welds: Applying their expertise to the challenging, hard-to-reach joint geometries that require exceptional manual dexterity and vision.

2. Robotic Automation (Consistency & Throughput): State-of-the-art robotic cells take over the bulk of the work:

- The "Lion's Share" Welding: The robots execute the longest, most repetitive welds, ensuring perfect consistency on every piece.

- Process Stabilization: Utilizing the robot’s high repeatability, all critical parameters (travel speed, angle, voltage) are locked in, eliminating variation.

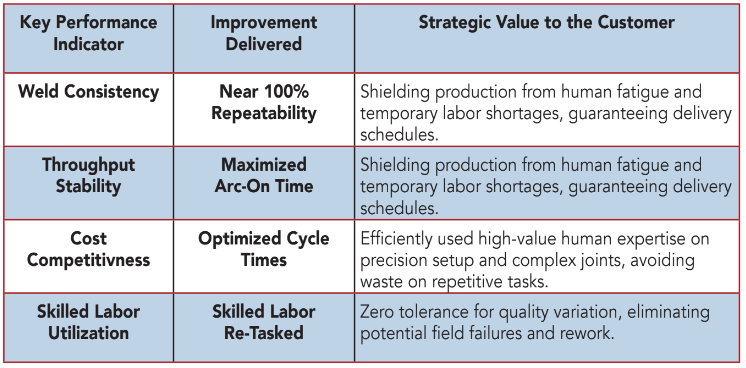

The Results: Consistency, Confidence, and Cost Control

By deploying this optimized hybrid cell, Power Brace Mfg. delivered immediate and measurable improvements, securing the customer's long-term production needs:

"This project is a perfect example of the innovation, collaboration, and results our partners have learned they can expect when teaming up with Power Brace Mfg. We don't just supply parts; we engineer solutions that guarantee supply chain reliability and competitive advantage."

Ready to stabilize your critical production and unlock competitive pricing? Contact Power Brace Mfg. today to discuss how our hybrid manufacturing solutions can secure your high-volume programs.

PowerBrace is ready to deliver. Call 515-452-0000 or visit PowerBraceMFG.com to request a quote or schedule a consultation for your next high-volume zinc electroplating project.

PowerBrace Manufacturing – Consistency. Capacity. Confidence.