Why Multi-Cell Robotic Welding Is the New Standard for High-Volume, High-Precision Manufacturing — And Why PowerBrace Is Leading the Future

INTRODUCTION: A NEW ERA OF MANUFACTURING RELIABILITY

Whether you’re a procurement manager sourcing steel assemblies, an engineer designing structural components, or a project manager tasked with hitting critical deployment timelines — one factor determines the success of your project:

Repeatable, high-quality welds delivered on schedule.

Today’s industries are scaling faster than ever:

- Solar and energy storage structures are larger and more complex.

- Defense programs demand absolute consistency and documentation.

- Construction and infrastructure projects require just-in-time reliability.

- OEMs need scalable production partners, not job shops.

- EPC firms can’t afford variability or supply chain gaps.

That’s why more companies are turning to PowerBrace Manufacturing’s Multi-Cell Robotic Welding Systems - a precision-driven, ISO-certified, automation-powered solution that eliminates variation, accelerates throughput, and reduces production risk across the entire supply chain.

Contact Us Now 515-882-4252WHAT MAKES MULTI-CELL ROBOTIC WELDING DIFFERENT?

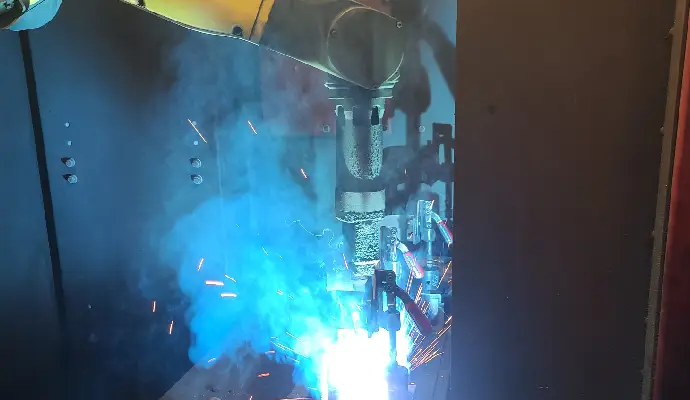

At PowerBrace, robotic welding is more than automation — it’s a complete manufacturing strategy.

We operate six advanced robotic welding cells, each built for:

- Large-format weldments up to 12 ft x 3 ft

- Complex geometries requiring multi-axis maneuverability

- High-duty-cycle, continuous operation

- Precision weld-path programming

- Perfect repeatability across hundreds or thousands of parts

No fatigue • No inconsistent bead size • No variation from shift to shift

This is welding engineered for industries that cannot accept anything less than perfection.

THE CHALLENGES POWERBRACE SOLVES

Manual welding can introduce deviations in:

- Heat input

- Travel speed

- Weld bead geometry

- Penetration depth

PowerBrace robotic cells eliminate variability entirely, resulting in:

- Predictable quality

- Zero rework

- Reduced downstream machining

- Stronger, cleaner welds

High-volume production is often slowed by:

- Labor shortages

- Shift changes

- Inconsistent throughput

- Multi-vendor coordination

PowerBrace removes those variables with:

- Six cells running concurrently

- Parallel production flows

- 24/7 capability where required

- Lean-managed schedules

This is how EPC firms and OEMs hit deployment deadlines.

Your welds need documentation, not assumptions.

PowerBrace operates under ISO9001:2015, enabling:

- Consistent QA/QC protocols

- Documented parameters

- Material and process traceability

For industries like defense, telecom, solar, and structural OEMs, this level of control is non-negotiable.

PowerBrace robotic systems excel at:

- Long linear welds

- Irregular geometries

- Multi-pass weld requirements

- Heavy structural assemblies

- Thick material sections

If your parts are oversized, intricate, or repeatable — our weld cells are optimized for them.

THE POWERBRACE DIFFERENCE — MULTI-SERVICE, END-TO-END MANUFACTURING

Here’s the differentiator no other robotic welding provider can match at this scale:

Every upstream and downstream process your welded part requires is handled inside PowerBrace’s facility.

Our supporting services include:

Laser Tube Cutting

- Up to 21’ length, 6” OD, .31” wall

- Perfect prep for robotic welding

Fiber Laser Table Cutting

- Up to 1” thick, 5’ x 10’ plates

- Bright-line precision ideal for structural components

HD Beveling Plasma (True-Hole)

- Up to 1.5” thick, 6’ x 26’ sheets

- Cuts & bevels prepped for welding integrity

Brake Press Forming

- 70–250 ton capacity

- Formed parts up to 10’ wide

CNC Machining

- Drilling, tapping, chamfering, countersinking

- Up to 55” parts

Acid Zinc Electroplating (ASTM B633)

- Large tanks: 12’ x 5’ x 17’

- Corrosion protection for manufactured assemblies

Kitting & Assembly

- Turnkey packaging, assembly, and ready-to-install delivery

RESULT: A SIN. A CONTROLLED PROCESS. A REDUCED COST.

By moving from a multi-vendor supply chain to PowerBrace’s unified ecosystem, clients gain:

- Fewer freight moves

- Zero dimensional mismatch between processes

- Streamlined QA across every operation

- Lower total cost of ownership

- Faster production cycles

- One accountable partner

This is why brands like Verizon, AT&T, and Google trust PowerBrace with high-volume steel components.

INDUSTRIES WE SUPPORT WITH MULTI-CELL ROBOTIC WELDING

- Solar & Renewable Energy - Tracker arms, structural beams, racking components, ground-mount assemblies.

- Battery & Energy Storage- Heavy welded enclosures, frames, integrated steel structures.

- Defense Manufacturing- High-reliability parts requiring certified documentation & traceability.

- Construction & Infrastructure- Reinforcement systems, brackets, frames, structural weldments.

- Telecommunications- Tower components, mounting systems, structural supports.

- OEM Manufacturing- High-volume repeatable assemblies requiring cost stability.

- EPC FirmsMission-critical schedules with zero tolerance for production variability.

WHY POWERBRACE LEADS THE FUTURE OF AUTOMATED WELDING

- Six robotic welding cells

- ISO9001:2015 certified processes

- Lean manufacturing efficiency

- Full-service fabrication & finishing ecosystem

- Extreme repeatability

- Faster throughput & reduced lead times

- Consistency across hundreds of thousands of parts

- Trusted by Fortune 500 & global technology leaders

CONTACT POWERBRACE TODAY!

Looking for a robotic welding partner you can trust with scale, complexity, and reliability? PowerBrace is ready.

Contact Us Now 515-882-4252